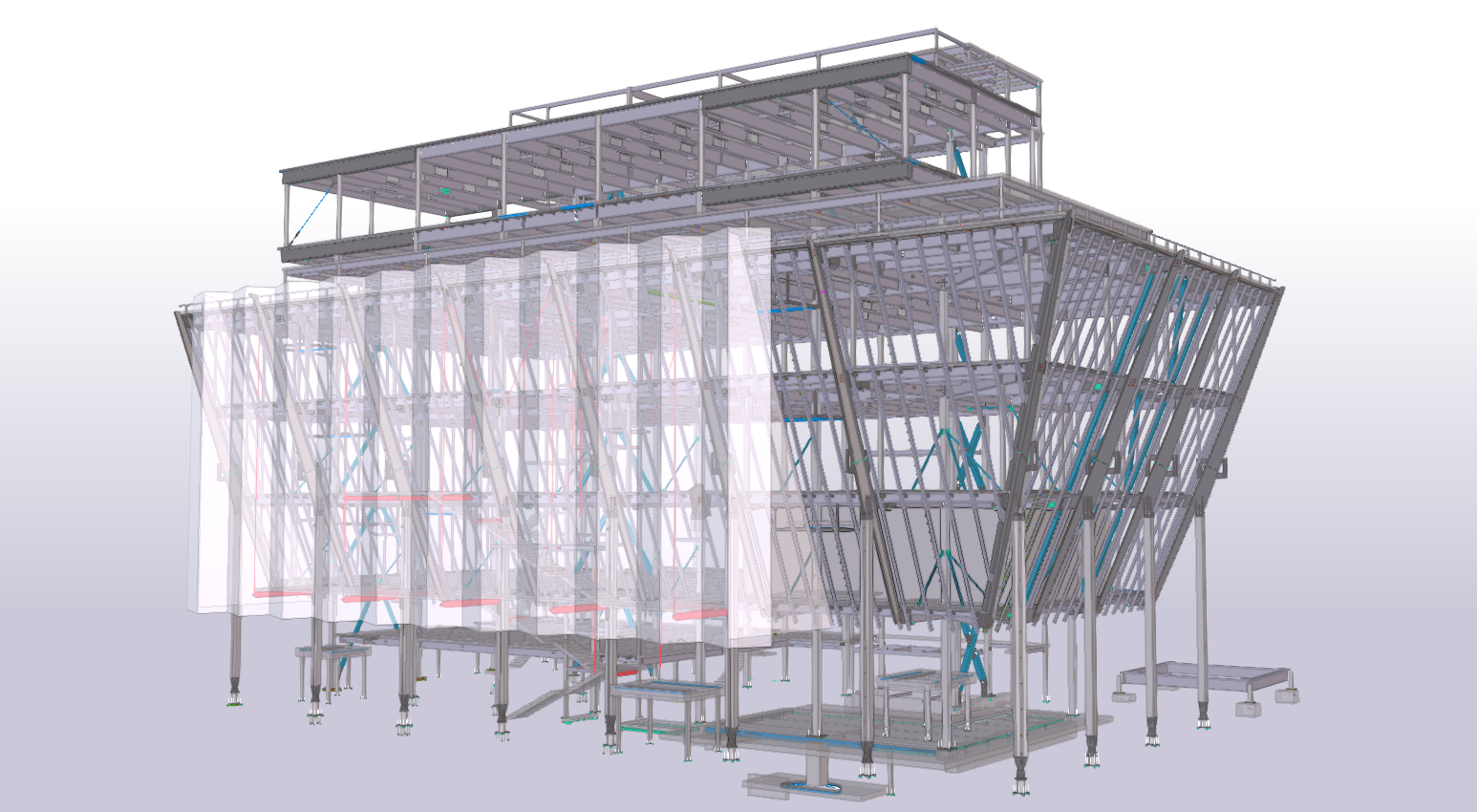

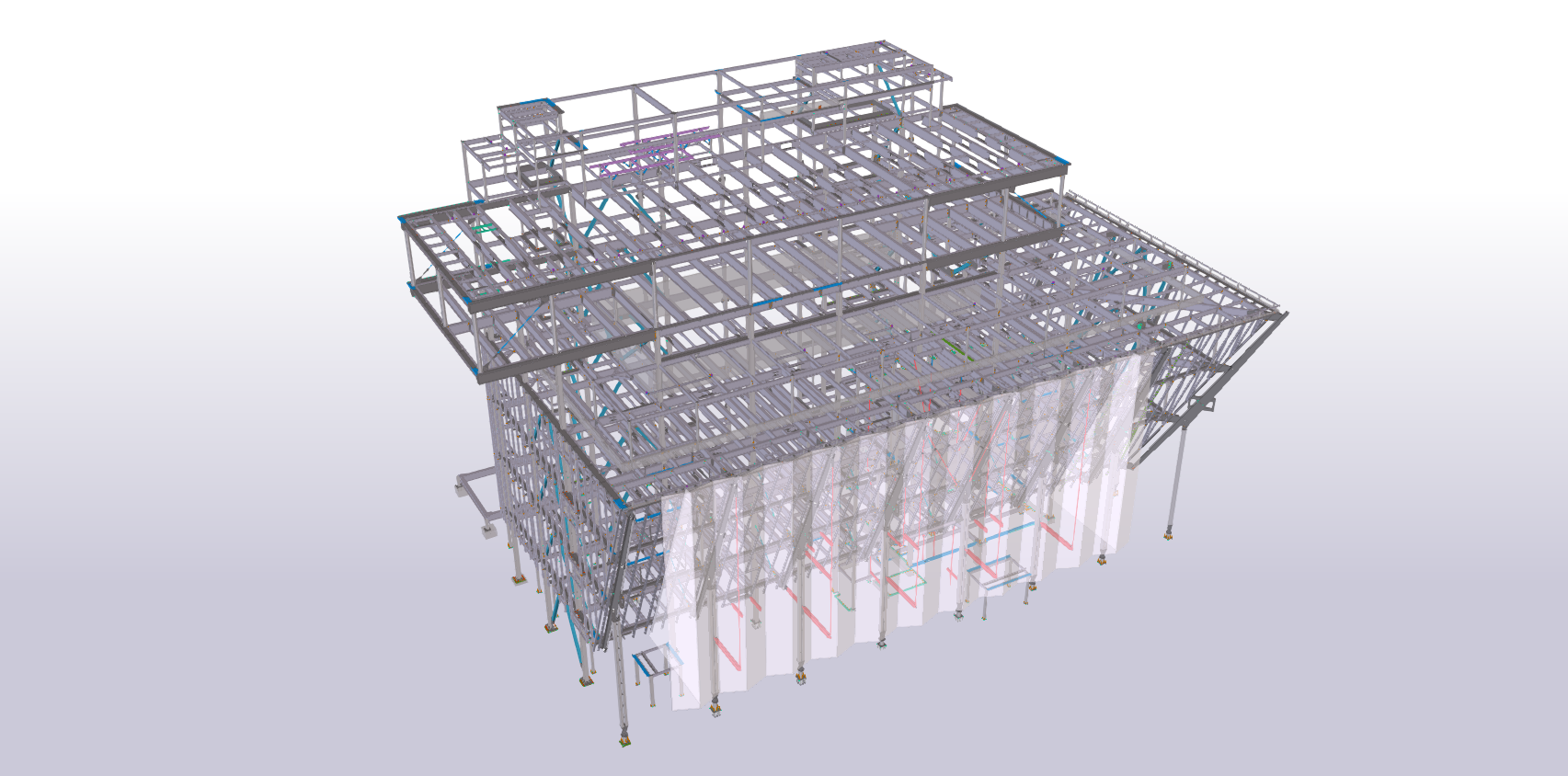

The new International Spy Museum in Washington will be built on top of the existing L’Enfant JBG property and will now lay directly in front of the glass atrium on L’Enfant Plaza. It will be an eight-story structure, with 140,000 square feet will include exhibition spaces, a lecture hall/theater, offices and a multifunction event space with sweeping views of DC. The design contains a 60-ft glass “veil” suspended in front of an enclosed “black box” exhibition space that allows people to move inside and outside, hiding in plain sight, which reflects on the spy theme of the museum.

International Spy Museum

Location: Washington D.C.

Year: 2018

Tonnage: 1500 tons

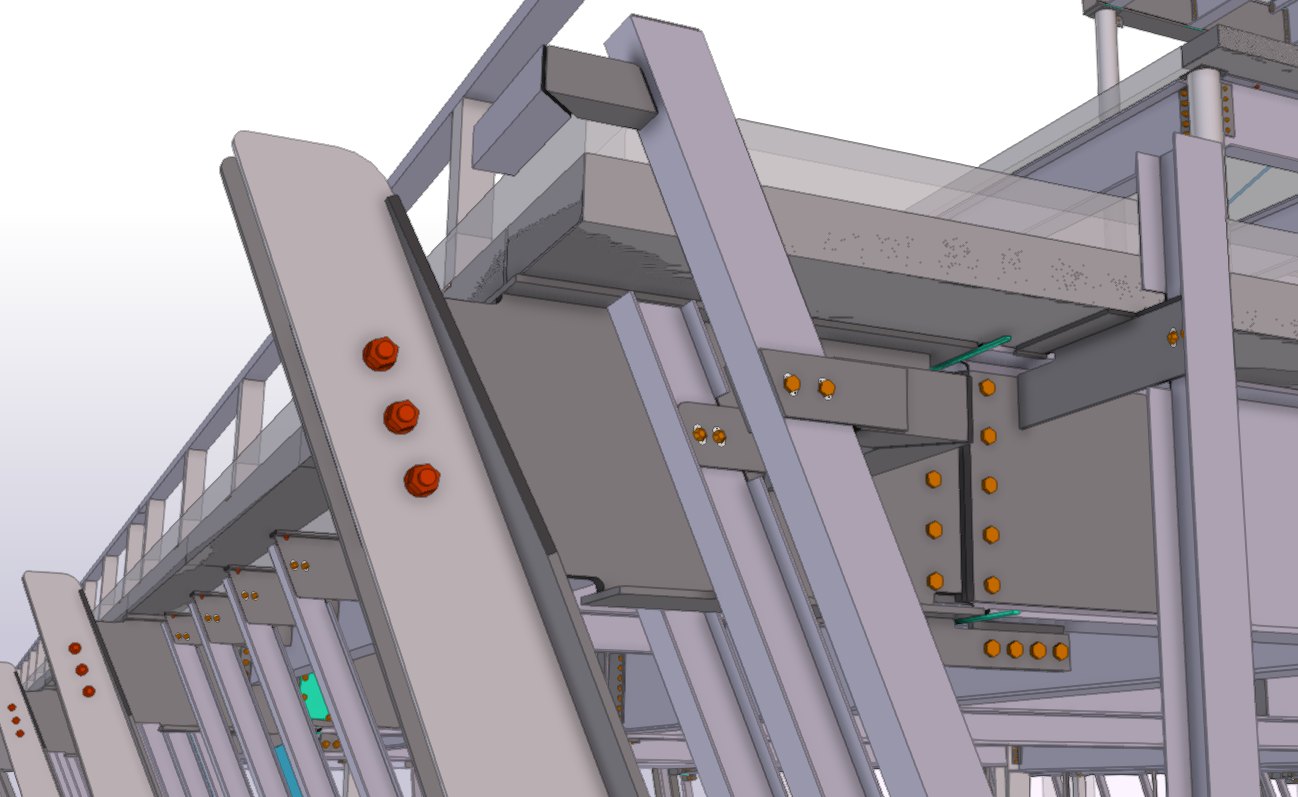

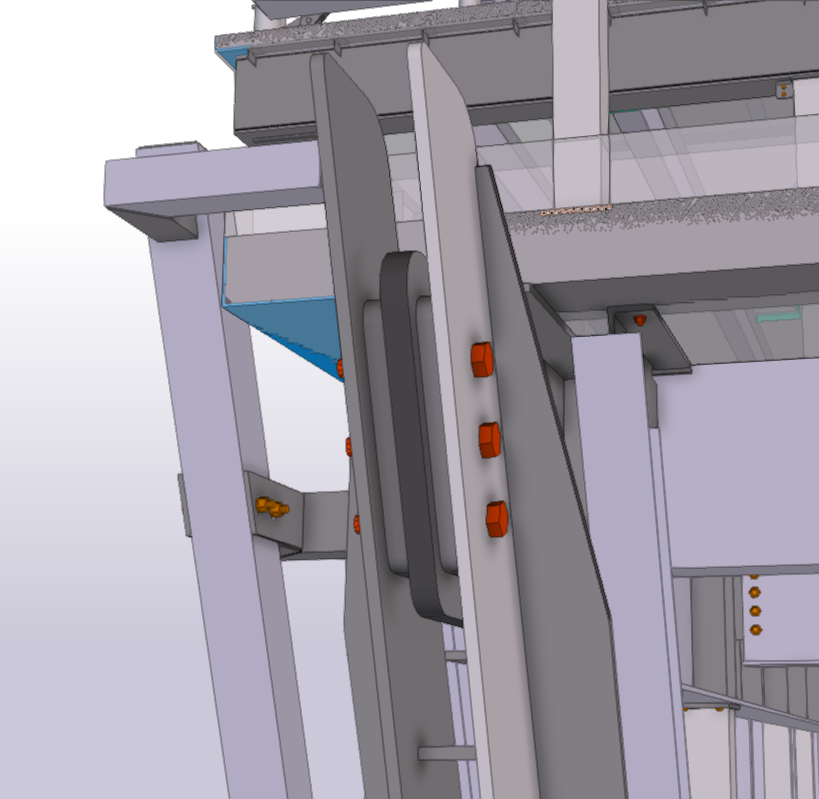

The challenge of this project was coordinating the veil structure, exterior stairs and building cover with other trades, as well as connecting the main structure with architecturally exposed structural steel (AESS) to view sloped columns.

A post-Steel Day event was hosted by AISC for students from George Washington University on the site that included an introduction to AISC, an overview of the project from SteelFab and a construction site tour of the project. The students gained an understanding of how steel is used to find an innovative perspective on building projects and how construction teams work together to meet expectations.

We, in cooperation with the steel fabricator SteelfFab Inc., have also received the Washington Building Congress Craftsmanship Award, which was presented to the project team leaders, Mikolaj Zak and Tomek Pasierb, for their exceptional work on a very challenging project.

This project was mentioned as an award winner in the 2018 April/May publication of the Bulletin Magazine.

Bulletin Magazine (https://www.wbcnet.org/uploads/Apr-May_2018_WBC_Bulletin.pdf )

“SteelFab’s work on the International Spy Museum project was exceptional starting from the design process, and continuing through installation. Unlike most steel structures in which the primary framing members are concealed from view, the sloping steel columns on the museum are a main design feature meant to be visible from afar. These columns were 75 feet in height when fully assembled, weighed 28,000 pounds each, and were all custom-built out of steel plates, taking almost 1,000 fabrication man-hours to complete per column.” – 2018 Washington Building Congress Craftsmanship Award description

Timelapse (https://public.workzonecam.com/projects/thejbgcompanies3/international/workzonecam/archive/timelapse?archiveId=Home)